Contents

Does Geofabric Break Down: In-Depth Analysis of Geotextiles

Introduction

Wondering about fabric breakdown? It happens indeed! By understanding fabric functions, we learn what causes wear. This article will shed light on why fabrics deteriorate and how to prolong their lifespan.

Geotextiles are permeable, synthetic fabrics. They comprise materials like polypropylene, polyester, nylon, and polyethylene. When used in construction, they filter, separate, or reinforce the associated soil.

Their robust composition makes them ideal for civil and environmental projects. These include land control, water management, and soil stabilization. But over time, all geotextile fabrics can weaken. Factors such as weathering or incorrect installation contribute to this. So, does fabric break down? Let’s dive in and discover!

Key Takeaways

- Geofabric uses natural fibers and synthetics like polypropylene, nylon, and polyester. It often uses thermoplastic polymers for flexibility.

- To predict a fabric’s breakdown rate, consider its fiber material, fabric type (woven or non-woven), manufacturing process, and exposure conditions.

- Water pooling can speed up nonwoven geotextiles’ disintegration. On the other hand, woven fabrics offer extended performance due to their strength.

- With correct installation and oxidation barriers, we can extend Geofabrics’ lifespan. This extends their returns on investment!

Understanding Geofabric and its Composition

Geofabric is composed of both natural and synthetic fibers; it can be woven or non-woven, and its use varies from project to project.

What is Geofabric?

Geofabric, a type of geotextile fabric, is crucial in many construction and engineering tasks. It consists of thermoplastic polymers such as polyester or polypropylene formed into flexible sheets.

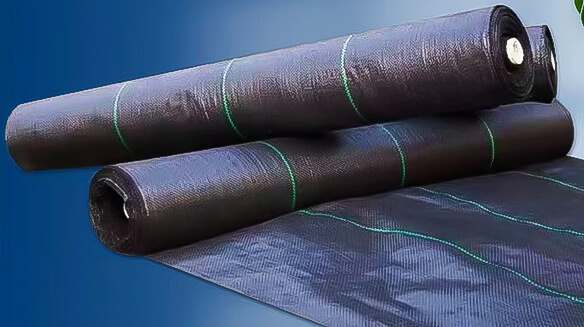

Geofabric comes in woven and non-woven types. It reinforces structures, offers drainage solutions, and prevents erosion in civil engineering projects. Its strength, rot-resistance, and often permeability make it an excellent choice for these uses.

In road infrastructure projects, fabric serves as a supportive base layer for large structures. Its long-lasting durability and the fiber and polymer selection in its production process contribute to its effectiveness.

woven geotextile

Types of Geofabric (Natural Fiber and Synthetic Fiber)

Geofabric, a type of geotextile fabric, is crucial in many construction and engineering tasks. It consists of thermoplastic polymers such as polyester or polypropylene formed into flexible sheets.

Geofabric comes in woven and non-woven types. It reinforces structures, offers drainage solutions, and prevents erosion in civil engineering projects. Its strength, rot-resistance, and often permeability make it an excellent choice for these uses.

In road infrastructure projects, fabric serves as a supportive base layer for large structures. Its long-lasting durability and the fiber and polymer selection in its production process contribute to its effectiveness.

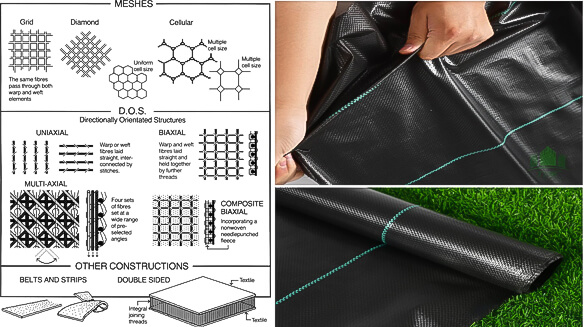

Difference between Woven and Non-Woven Geofabric

Woven and non-woven geotextiles have distinct benefits based on the job requirements. They typically come from polyester or polypropylene yarns or fibers. These offer different levels of strength, elongation, weight, cost-effectiveness, and permeability for drainage.

The primary difference between these fabric types is in their properties. Woven fabrics have layers interlaced together for reinforcement. This gives them more tensile strength and strain. On the other hand, non-woven materials lack this reinforced strength and deteriorate faster over time.

Non-woven geotextiles excel in water pervasion. This makes them useful for filtration. They effectively drain water in landscaping projects like French drains or driveways. However, their structural stability is lower compared to woven fabrics, necessitating regular maintenance.

How Geofabric is Used in Various Applications

Geofabrics, or geotextiles, are special fabrics used in diverse earthwork projects, including dams, buildings, and construction sites. They’re made from robust synthetic fibers like polyester or polypropylene, and occasionally natural fibers such as jute. They are used to control soil movement and prevent erosion, providing essential soil stabilization in civil engineering projects.

The choice of fabric depends on its physical properties and the needs of each project. Their impressive resistance to breakdown or degradation over time, thanks to their composition, makes fabrics an ideal choice for most environmental engineering jobs.

Construction experts often use a mix of materials with the fabric to enhance its performance. For example, in large-scale building works where land stability is critical, like during excavations or foundation laying, they use layered meshes. These consist of a layer of gravel, geomembranes, and reinforced concrete slabs, all held together securely. Even grass turf is used alongside the stabilized area, held underneath securely through reinforcing bartacks.

In essence, fabrics are an incredibly useful tool that adds essential strength to construction projects, ensuring their successful completion while maintaining peace of mind for those involved.

Anti-erosion geotextile for dyke construction

Does Geofabric Breakdown?

Answering the question of geofabric’s longevity requires considering key factors like water pooling, lifespan, and degradation rate. These elements significantly impact the material’s endurance. Let’s delve deeper to understand how geofabric can degrade over time.

- Water Pooling: This can lead to quicker disintegration, especially for non-woven geotextiles. They are known for their superior water permeability but can weaken if water continually pools on the fabric surface.

- Lifespan: Both the lifespan and durability of geofabric depend on its type and use. For instance, woven geofabrics, with their reinforced strength, can deliver long-lasting performance when maintained over time.

- Degradation Rate: The degradation rate of geofabric is influenced by factors such as fiber material, manufacturing process, and exposure conditions. For instance, exposure to sunlight and harsh weather conditions can hasten the breakdown process.

Proper installation and use of oxidation barriers can help extend the lifespan of geofabric. This will ensure a better return on investment in the long run, underscoring the importance of understanding these factors in selecting the right geofabric for your project.

Factors Affecting Geofabric Breakdown

The fabric’s physical structure largely determines its durability and lifespan. Generally, synthetic materials like polypropylene offer more strength than natural fibers like cotton or jute.

Non-woven geotextiles, being more porous than their woven counterparts, can break down faster. Factors like UV and chemical exposure, temperature changes, mechanical stress, and water pooling can all speed up fabric degradation.

Also, improper installation or lack of maintenance can lead to faster wear. It’s crucial for geotextile applications to use proper bonding methods to attach fabrics. This helps maintain performance and integrity over a longer period.

The Lifespan of Geofabric

Geofabric, robust and long-lasting, serves many civil engineering needs. It aids in managing drainage systems and controlling soil erosion. The fabric’s lifespan largely relies on the base polymer and fiber type used.

When well-crafted and treated right, these fabrics can endure up to 20 years. Some even last over 200 years when buried. Yet, exposure conditions play a big role in fabric lifespan. Some products break down quickly if exposed to UV rays, water, chemicals, or microbial environments.

Preventing premature degradation means proper installation and use of oxidation barriers. This varies based on the environment, like rainfall amounts. For the best results, follow the manufacturer and designer’s instructions carefully. This ensures the right application and maximizes the fabric’s lifespan.

Effects of Water Pooling on Geofabric

Water pooling can harm fabric, causing it to break down and work less effectively. In particular, nonwoven geotextiles might break down faster than woven ones due to excessive moisture.

If you’re working on construction projects with geotextile structures, keep this in mind. You want to ensure long-lasting durability and success in controlling erosion. Poor drainage, which could cause water to accumulate on fabric edges, may also lead to less soil stability. Trapped moisture can weaken the ground over time.

Further, without a good drainage system, more seepage or runoff could weaken the material’s ability to retain mud during heavy rain. So, keep an eye on drainage when working with geotextiles!

Measures to Extend the Lifespan of Geofabric

Geofabric is a durable and versatile material that can be used in a wide range of construction applications. However, over time the lifespan of geotextiles will start to decrease due to environmental factors such as UV rays or water pooling.

To extend the life expectancy of geotextiles, various treatments, and blending techniques can be applied. Treatments include chemical and mechanical fixing solutions like stitching with polyester yarns which prevent abrasion damage.

In addition, fiber properties like weight per unit area as well as selection should be considered when choosing fabric products for extended durability and performance retention levels. Blending synthetic materials such as polypropylene provide enhanced strength while increasing resistance against puncture damage from sharp objects on-site during installation or while in use later on.

Ensuring proper installation is also key if you want your product to last longer; following all manufacturer guidelines carefully minimizes potential harms caused by improper usage which may reduce fabric strength leading to premature breakdown.

Conclusion

Geofabric provides numerous benefits in civil engineering tasks, such as soil reinforcement, drainage systems, and surface materials. It also helps prevent soil erosion and stabilizes the land.

However, geotextiles are not immune to degradation over time. Water pooling and harsh environmental conditions can cause wear and tear. The fabric’s breakdown rate depends on factors like the fiber material used and the manufacturing process.

If you want to prolong a fabric’s life, protect it from intense sunlight, UV radiation, and harsh conditions that may speed up its degradation. Remember, polypropylene fibers can be tough on fabrics. Thus, opting for natural fibers may offer better durability than synthetic materials in your geotextile selection for a project.

FAQs

1. What is geo fabric and what is it used for?

Geofabric, a special kind of fabric, brings added strength and stability to retaining wall structures during heavy rains or severe weather. The fabric usually incorporates multiple layers of high-strength nylon, making it far more durable than traditional building materials like concrete or brick.

2. How does fabric work?

Geofabric offers a protective buffer between the soil under retaining walls and the exterior components or top layers. This barrier prevents soil shifting due to moisture seepage from either above or below ground level. Factors such as saturation rates around wells or creeks can affect the amount of water entering the structure.

Geofabric helps maintain strong bonds around all sides of each layer. It doesn’t just rely on the internal components to handle weight loads or pressures from various directions. This helps prevent collapses over time, even with changing weather patterns throughout the year, like potential heavy floods.

3. Does geo fabric break down over time?

No, Geofabric is designed for long-term durability and can withstand severe environmental conditions. That’s why it’s a key component in shoreline construction projects, as mentioned in many global marine studies. Without it, such projects would be cost-prohibitive due to erosion risks.

Even the highest quality Geofabrics won’t break down easily unless exposed to extreme conditions like acid rain, beyond the manufacturer’s detailed specifications. To ensure the product performs optimally, a certified professional should oversee its usage, adhering to the normal operating environment specified in the design plans.

Regular maintenance, aligned with seasonal changes, can further extend its life. Quality control processes should be in place for efficient functioning throughout the project cycle, meeting the predetermined deadline.