Contents

- What is the Purpose of Geotextile Fabric? Uses of Geotextiles

What is the Purpose of Geotextile Fabric? Uses of Geotextiles

Meta: Explore the versatile applications of Geotextile Fabric in soil stabilization and erosion control. Uncover how this unique synthetic material boosts drainage, mitigates soil erosion, and curtails weed proliferation, promising a resilient and easy-to-maintain landscape. Perfectly answers the question, “What is the Purpose of Geotextile Fabric?”

Introduction to Geotextile Fabrics: History and Purpose

Geotextile fabrics mark a transformative milestone in the textile industry. These materials, tailor-made for geotechnical environments, shape our approach to complex projects in land or water settings. The birth of nonwoven geotextile fabric signaled a significant shift in this field. Though designed for practicality, their utility goes beyond the obvious.

Geotextile fabric champions several purposes. It acts as a robust defense against soil erosion and assists in land stabilization. Moreover, it contributes to the creation of effective water drainage, filtration, and protection systems. Beyond these roles, geotextile fabrics find usage in road construction, agriculture, and coastal applications for dune stabilization.

The genesis and objectives of geotextile fabric are intertwined. Tracing back to ancient times, people utilized natural resources to enhance soil conditions and build infrastructure, revealing the potential of these simple materials. Modern geotextiles, with enhanced strength and durability, testify to the innovative prowess in the textile domain. Hence, the evolution and roles of geotextile fabrics underscore their significance in our day-to-day lives.

Understanding the Use of Correct Geotextile Fabrics in Construction

Deciphering the proper application of geotextile fabrics in construction is crucial. Applied correctly, geotextiles elevate the performance and lifespan of construction projects. They serve numerous functions, laying a sturdy foundation for any construction site. The key to proper geotextile use lies in choosing the best material for your unique requirements.

Geotextile fabrics are diverse, and often employed in construction for separation, reinforcement, filtration, drainage, and protection. The right selection hinges on site conditions and project demands. Various types of geotextiles, each offering different tensile strength, permeability, and durability, are available. However, not every geotextile fabric suits all construction scenarios.

In construction, using the right geotextile fabric is pivotal to ward off future complications. Wrong usage can trigger project delays, cost escalations, and structural instability. Geotextiles are not universal fixes, hence, proper understanding and application are key to harvesting their benefits in construction.

Keep in mind, geotextiles are designed for a specific purpose. Whether it’s curbing soil erosion or enhancing water flow, these resilient materials play a central role in modern construction. To tap into their benefits to the fullest, the right selection and usage of geotextiles are indispensable.

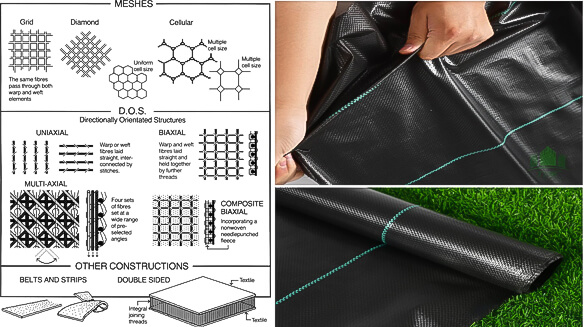

Delving into the Contrast: Woven Geotextile and Non-Woven Geotextiles

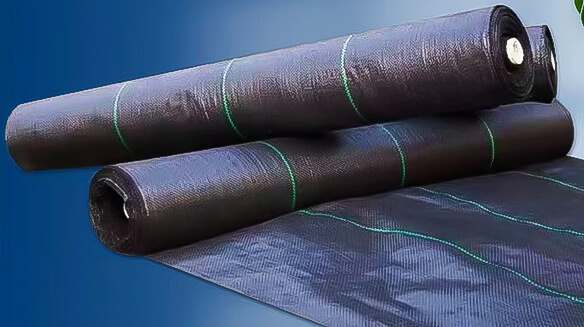

Let’s start by unraveling the differences between woven and non-woven geotextiles. Weaving two sets of threads into a grid-like pattern creates woven geotextile fabric. This fabric boasts high durability, ideal for high-strength demands in construction and geotechnical projects. Its main drawback? Limited permeability due to the tight weave.

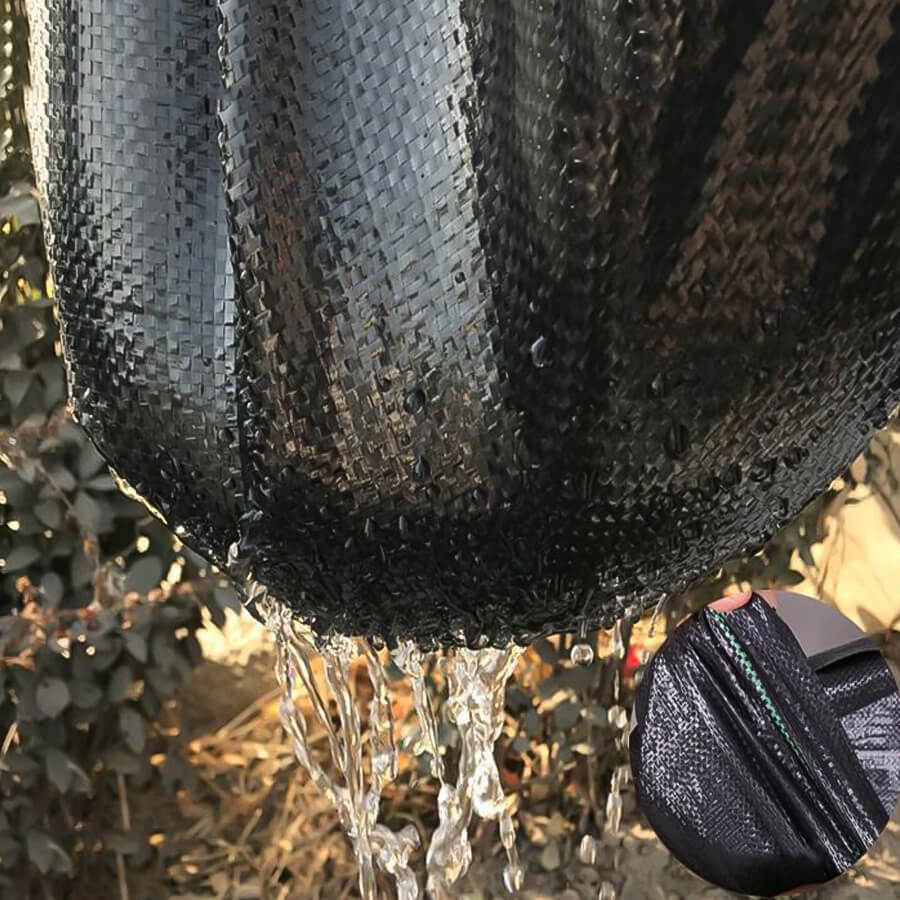

In contrast, non-woven geotextiles come to life by bonding fibers together. This process forms a random, felt-like fabric mat. Known for superior drainage properties, non-woven geotextiles boast high permeability. They are the top pick for projects needing good drainage and filtration, such as behind retaining walls or under roads.

Knowing which geotextile suits your needs guarantees project success. Each type has unique strengths and weaknesses. Understanding the functionality and uses of woven and non-woven geotextiles guides you toward informed choices about these versatile, plastic-based materials.

The Function of Geotextile Fabric as a Filter

Geotextile fabric majorly performs filtration and separation. These special fabrics come designed with intricate science and precise information. They manage drainage by allowing water to seep through while filtering out sediments. As a filter fabric, geotextiles let water pass but hold the soil in place, preventing erosion. Road construction and erosion control commonly use them for their effective soil separation technique.

Geotextile fabrics show their versatility by also acting as stabilization and reinforcement materials. Their proficient filtration function secures the structure of construction projects, ensuring long-term stability. Today, more attention goes towards choosing the right geotextile fabric to fully leverage its function and ensure a successful application.

Differentiating between woven and non-woven geotextiles is crucial, as each type has unique purposes. Woven geotextile fabrics bring excellent strength and load-bearing capabilities to the table, while non-woven geotextiles shine in providing superior filtration and separation. With continuous advancements in geotextile design and science, their importance and varied uses keep growing.

The Importance of Geotextiles in Modern Construction Projects

Grasping the value of geotextiles is key to understanding today’s construction. Geotextiles have spurred a revolution in the construction industry. They bring innovative solutions to a variety of projects. Among the most versatile materials used, geotextiles mainly enhance soil characteristics, thus boosting the strength and durability of roads and other construction sites.

Geotextiles are not mere additions; they critically impact the strength and stability of structures. While their functions are numerous, geotextiles mainly stabilize soil, increase its strength, and improve drainage. In road construction, geotextiles prevent the mixing of dissimilar materials. This separation function helps maintain the road structure and lengthens its lifespan.

The construction industry no longer questions the value of geotextiles. It acknowledges and appreciates their function. Their high strength and permeability make them invaluable, managing water flows and offering effective protection. The use of both woven and non-woven geotextiles, each with specific properties, is significant. In conclusion, geotextiles’ importance in modern construction is undisputed. Their role in guaranteeing the stability and longevity of structures is unparalleled.

Choosing the Right Geotextile Fabric

Choosing the right geotextile fabric is essential for successful applications. Read on to learn more about how you can do so.

Consider project requirements

As a project manager, considering the right geotextile fabric for your project is essential. Different types of fabrics are available with various features and properties that need to be taken into account when selecting the ideal fabric for a given task.

It’s important to analyze how permeable or strong you need the fabric to be as well as what soil conditions will come into play during construction. Depending on these requirements, woven double-layered fabrics may assist in providing both reinforcement and water absorption needs whereas non-woven fabrics are more suitable for filtration applications where strength is not required.

Additionally, consulting experts can help determine which type of geotextile material would work best for specific job site conditions before making any final decision about purchasing this specialized material.

Determine soil conditions

Before selecting the right geotextile fabric for your project, it is essential to understand and evaluate the soil conditions. This includes evaluating the moisture content, the composition of soils, compaction level, and permeability.

Knowing these details will help you determine what type of geotextile fabric is best suited for your project needs. For example, if your soil has high levels of clay or a low drainage rate then it’s important to install a heavy-weight woven material that features excellent tensile strength for reinforcement purposes.

On the other hand, non-woven fabrics are better suited when dealing with higher levels of organic soils or free-draining applications like retaining walls or erosion control projects.

To ensure maximum effectiveness in any given application it’s essential to conduct some tests on the subgrade soils and consult experts who have experience with geotextiles before beginning construction.

Select the appropriate fabric type and weight

It is important to select the appropriate fabric type and weight when it comes to geotextile fabrics, as this can determine the performance of the material in various applications.

The two most commonly used types are woven and nonwoven, with non-wovens usually measured by their weight in gsm (grams per square meter) or ounces per square yard. This determines several characteristics including filtration, drainage, and puncture resistance abilities.

Geotextiles also vary in terms of thickness, strength, porosity, etc., so these too need to be considered before making a selection. Woven fabrics have a higher tensile factor than non-woven ones, which makes them good for reinforcement use such as roadways projects where stability and impact are key considerations.

Moreover, understanding project requirements including soil conditions along with consulting experts helps choosing the right fabric type that leads to maximum performance in gravel road applications or for waterproofing purposes.

Consulting with experts

When selecting the most suitable geotextile fabric for a project, it is crucial to consult with experts. Their expertise in this field can provide invaluable guidance and advice when it comes to choosing the appropriate fabric type and weight that provides the right balance between tensile strength, durability, and performance.

They will also be able to assess soil conditions that may affect water permeability or stability of ground elevation which could impact how effective the chosen material is in its intended application.

Consulting an expert ensures they recommend a geotextile solution specific to your project needs for the successful implementation of erosion control, stabilization, drainage systems, etc. Ultimately, their knowledge can help determine if your chosen product has enough tensile strength for adequate reinforcement or waterproofing causing your project to run smoothly as planned according to budget and timeline constraints.

Conclusion

Geotextile fabric has proven its usefulness and versatility in various civil engineering, construction, landscaping, and environmental applications. Its many benefits include the prevention of soil erosion, improved soil stability, enhanced drainage, increased lifespan of infrastructure as well as reduced maintenance costs.

It is important to select the right geotextile fabric for each project based on the requirements and existing conditions of the site. This will ensure that it performs its role effectively while minimizing any risks from overloading or incorrect installation.

Geotextiles are a valuable tool for solving two-dimensional problems such as separating different soil layers and building support structures without having to excavate the ground together providing excellent filter performance when used within a drainage system or around pervious pavements.

Frequently Asked Questions

1. What is Geotextile Fabric?

Geotextile fabric, a permeable synthetic material, is crafted from fibers like polypropylene, polyethylene, or nylon. This composition grants it impressive durability and high tensile strength. Predominantly utilized in civil engineering, this fabric strengthens and supports structures including roads, railways, and drainage systems.

2. How do Geotextiles Guard Against Erosion?

Geotextile fabrics are commonly deployed on slopes and coastal areas. By bolstering surface stability, they aid in counteracting erosion caused by robust winds or intense rainfall. Additionally, these fabrics promote deeper root penetration for grass, further enhancing stability. The use of anchors or alternative sediment control measures amplifies their effectiveness.

3. How do Geotextiles Improve Roadways?

Geosynthetic textile membranes have the resilience to withstand minor ground shifts over time without degradation. They efficiently prevent water accumulation beneath pathways, which could otherwise cause cracks and eventual breakdown of asphalt due to repetitive freeze-thaw cycles. By embedding geotextile materials within the surrounding soils during resurfacing, workers gain the additional thickness and support essential for the long-term repair of potholes formed by ongoing traffic.

For more precise or topic-related adjustments, please provide the content in a clear format, and I’ll be eager to assist further.