Contents

What is Non-Woven Geotextile? Benefits Of Nonwoven Geotextile

Introduction to Nonwoven Geotextile and its Various Applications

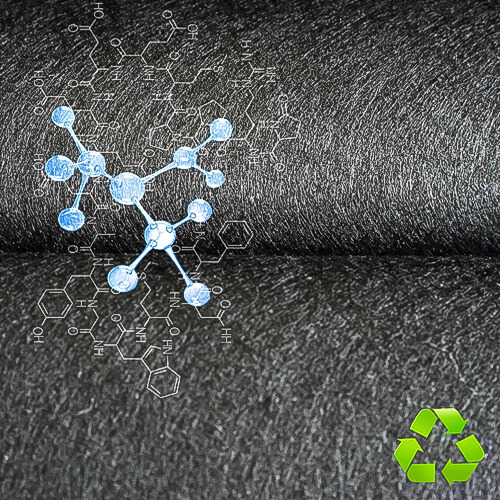

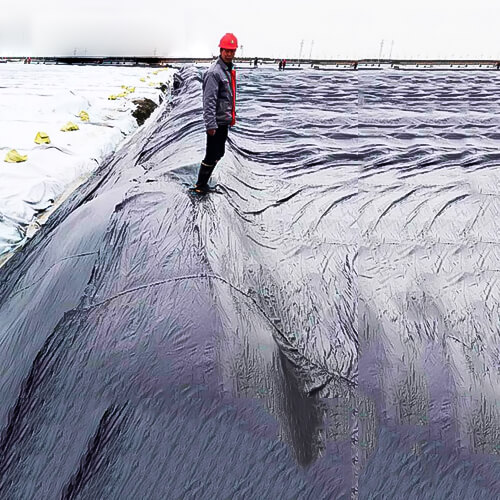

Non-woven geotextiles, crafted from synthetic fibers such as polyester or polypropylene, resemble felt in appearance. They’re produced by bonding materials, yielding a strong product used in diverse sectors.

These geotextiles have various uses, including soil stabilization and drainage construction. In soil tasks, they manage movement and curb erosion, enhancing stability.

For pipeline projects, this fabric seals spaces to avoid leaks. Especially in plastic drainage pipes, it acts as a protective barrier, boosting pipe performance.

Renowned for their durability, nonwoven geotextiles are invaluable in numerous undertakings. They blend functionality with longevity, enriching each application.

In essence, both nonwoven and woven geotextiles represent efficiency and adaptability. Grasping their capabilities can elevate a project’s caliber and lifespan.

Non-woven geotextiles

Overview and Utilization of Geotextiles, Woven, and Nonwoven

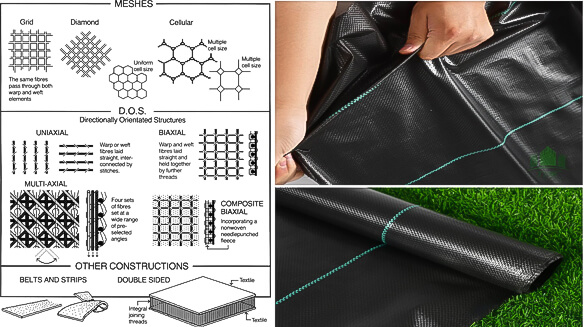

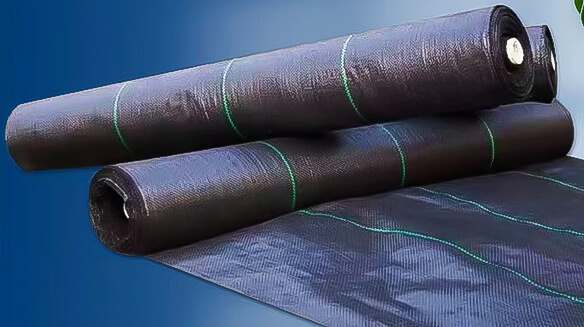

Geotextiles, woven and nonwoven alike, offer dynamic solutions, especially within landscape and civil engineering realms. Woven geotextiles, known for their interwoven design, provide a robust foundation in projects demanding soil stability. Given their ability to bear substantial weight, they’re pivotal in roadworks and alike.

On the flip side, non-woven geotextiles, despite lacking a woven structure, boast immense strength from their fibrous network. Variants like linq gtf shine for soil filtration and separation, marking them as top picks for landscape tasks. Beyond landscaping, they’re crucial in drainage and erosion counteractions.

The core difference? Manufacturing. Woven geotextiles emerge from interwoven threads, yielding a sturdy fabric. Non-woven variants result from bonding or tangling fibers, hence the ‘non-woven’ label. This distinction also influences their specific uses and properties.

In summary, both geotextile types are industry staples, each with unique merits. Knowing which suits your needs ensures project excellence.

Nonwoven geotextile drainage application

Drainage and Separation: Key Applications of Nonwoven Geotextile Products

Nonwoven geotextiles stand out for their versatility, especially in drainage and separation tasks. In drainage, they facilitate efficient fluid removal. Their structure ensures fluid flows smoothly, addressing concerns like waterlogging.

Separation is another forte. Nonwoven geotextiles distinctively separate soil layers. In construction, they avert layer mixing, safeguarding a project’s structure. Their adoption in construction underscores this utility.

Comparing woven to nonwoven geotextiles highlights application appropriateness. The nonwoven type excels in drainage and separation, outperforming woven variants. For construction projects prioritizing these functions, nonwoven is preferable.

Essentially, nonwoven geotextiles champion “prevention over cure.” They proficiently tackle drainage issues and ensure layer separation. These products pave a future where construction hitches, especially in drainage, are minimal. Their significance in construction and drainage is undeniable.

Nonwoven geotextile drainage and separation

Difference Between Woven Geotextile and Nonwoven Geotextile

Woven and nonwoven geotextiles differ fundamentally in their construction. Woven geotextiles result from weaving threads tightly, either diagonally or perpendicularly. This method offers robust erosion control, ensuring stability. Ideal for tasks like road construction, woven types shine where tensile strength is paramount.

In contrast, nonwoven geotextiles emerge from bonding or felting fibers, forming a felt-like structure. They prioritize drainage and separation, excelling in erosion control when water flow and filtration matter. Landscaping, especially erosion control, frequently employs nonwoven variants.

Each type boasts specific strengths. Woven geotextiles resist punctures and abrasions, fitting settings needing stability and load distribution. Conversely, nonwoven types, with enhanced liquid and gas permeability, reign in drainage and containment tasks.

Both types are indispensable for soil stabilization and erosion control. Their purpose: retain soil while allowing water passage. The choice between them hinges on the project’s nature and erosion control intensity. Together, geotextiles champion environmental preservation, curbing erosion, and fostering terrain’s healthy evolution.

Difference Between Woven Geotextile and Nonwoven Geotextile

Woven vs Nonwoven: Distinct Uses in Drainage and Separation Applications

Understanding geotextiles requires distinguishing between woven and nonwoven varieties due to their distinct applications, especially in drainage and separation. Non-woven geotextiles excel in reinforcement, filtration, and drainage. Marrying durability with permeability, they shine in drainage scenarios with high water flow.

Conversely, woven geotextiles serve stabilization and reinforcement needs. Tailored for strength, they’re key in road construction, offering reliable separation and reinforcement. However, their reduced permeability makes them less suited for filtration or drainage tasks.

Both types, woven and non-woven, efficiently meet project demands, whether for reinforcement, filtration, or separation. The optimal choice hinges on your project’s specific needs.

Nonwoven Geotextile in Modern World: Essential Products for Screen and Drainage

Nonwoven geotextiles stand out in screening and drainage applications. Crafted from synthetic fibers like polyester and polypropylene, these geotextiles possess distinctive features tailored for diverse uses. Their unmatched filtration prowess makes them invaluable in drainage activities.

Unlike conventional textiles crafted through weaving or knitting, nonwoven geotextiles emerge from woven slit film or permeable landscape fabric.

Each geotextile variant serves specific needs. Depending on your project’s specifics, either woven or nonwoven geotextiles might be optimal. Regardless of choice, geotextiles guarantee enhanced project efficiency and durability due to their filtration efficiency and water permeation.

Nonwoven Geotextile in Modern World: Essential Products for Screen and Drainage

Understanding the Role of Woven and Nonwoven Geotextiles in Today’s Industries

Distinguishing between woven and nonwoven geotextiles is pivotal for project success. Each offers unique attributes vital for specific tasks.

Woven geotextiles focus on reinforcement. Engineered to shoulder heavy loads, they stabilize subgrades, supporting diverse construction undertakings. Conversely, nonwoven geotextiles, often termed non-woven, are game-changers in multiple sectors. They shine where durability, erosion control, and drainage are paramount. Their prowess in managing erosion, halting soil shifts, and aiding drainage make them invaluable, especially in construction and environmental domains where water flow regulation is critical.

Producing nonwoven geotextile fabric entails crafting a robust product, resilient to harsh environments and demanding physical challenges. Its distinct build enables exceptional filtration and drainage. Consequently, nonwoven geotextiles excel in erosion management, drainage enhancement, and subgrade separation, becoming many industries’ go-to solutions.

Conclusion

Nonwoven geotextiles play a pivotal role across diverse industries, excelling in soil control, filtration, separation, drainage, and reinforcement. Crafted from polyester or polypropylene fibers, they boast robustness and longevity, thanks to thermal or chemical bonding processes like needle punching.

Widely employed in civil engineering ventures such as roadworks or landscape erosion control, these geotextiles are not just about physical prowess. They also present a cost-effective solution, often eliminating the need for supplementary materials and slashing labor costs due to quicker installation.

With their myriad benefits, nonwoven geotextiles are indispensable tools, adeptly addressing contemporary project challenges, regardless of scale.

FAQs

1. What are the advantages of using nonwoven geotextiles?

Non-woven geotextiles bring many benefits based on their use. They boost bearing capacity and ensure stability. They also excel in filtration and control of water flow. These textiles protect against frost heave and UV rays. Importantly, they prevent cracks, allowing safe vertical shifts while maintaining surface bonds.

2. How durable is nonwoven geotextile?

Non-woven geotextiles typically have high durability ratings when discussing strength capabilities with various levels offering long-term performance with minimal fiber breakage over time even under mechanically harsh conditions such as extreme temperatures or deformations due to vehicular traffic etc.. Additionally – products developed specifically for certain industrial environments can prove especially effective for extending lifespans or resisting damage inflicted upon them so it’s best practice if looking into going this route – assess all available options thoroughly before making any purchasing decisions).

3. Is non-woven geotextiles waterproof?

Non-Woven Geotexteil features some level of permeability but not actual waterproofing like you would find with conventional fabrics – so although it may be able to resist small amounts of moisture/dirt from seeping through – larger volumes will inevitably work their way past initial barriers thus ultimately preventing any total degree of waterproofing that could exist otherwise (i.e., laminated layers, foam core interiors, etc.).